It’s been a couple of years and life has flown by. Time flies when you’re having fun, and I’m grateful when I say I’ve been busy. Life has been good. Healthy and happy family, work has been solid, and I’m fortunate to be able to enjoy my hobbies. I owe you all an update, but that’s not why I’m writing.

About two weeks ago, my day started like any other day. Getting woken up by Max (our beloved cat), feeding him, and sleepily reading through my emails. One caught my attention in particular: Jack Lawrence had passed away. Yes, the Jack Lawrence.

When you buy a vintage Saab, especially a Sonett, you learn who Jack is pretty damn quick. After all, there are very few solid sources for Sonett parts. But dealing with Jack and his lovely wife Pat was not just buying an auto part. You got to deal with arguably the most knowledgeable Sonett person on the planet. Think about that for a minute. If you owned a Shelby GT500, wouldn’t it be awesome to pick up the phone and talk to Carroll Shelby? If you had a new Corvette, how cool would it be to zip an email to Chief Engineer Tadge Juechter (or maybe Zora Arkus Duntov for you vintage Vette guys)? Dealing with someone who has immersed themselves 100% into their area of expertise is always a pleasure, you know you’re going to be in good hands!

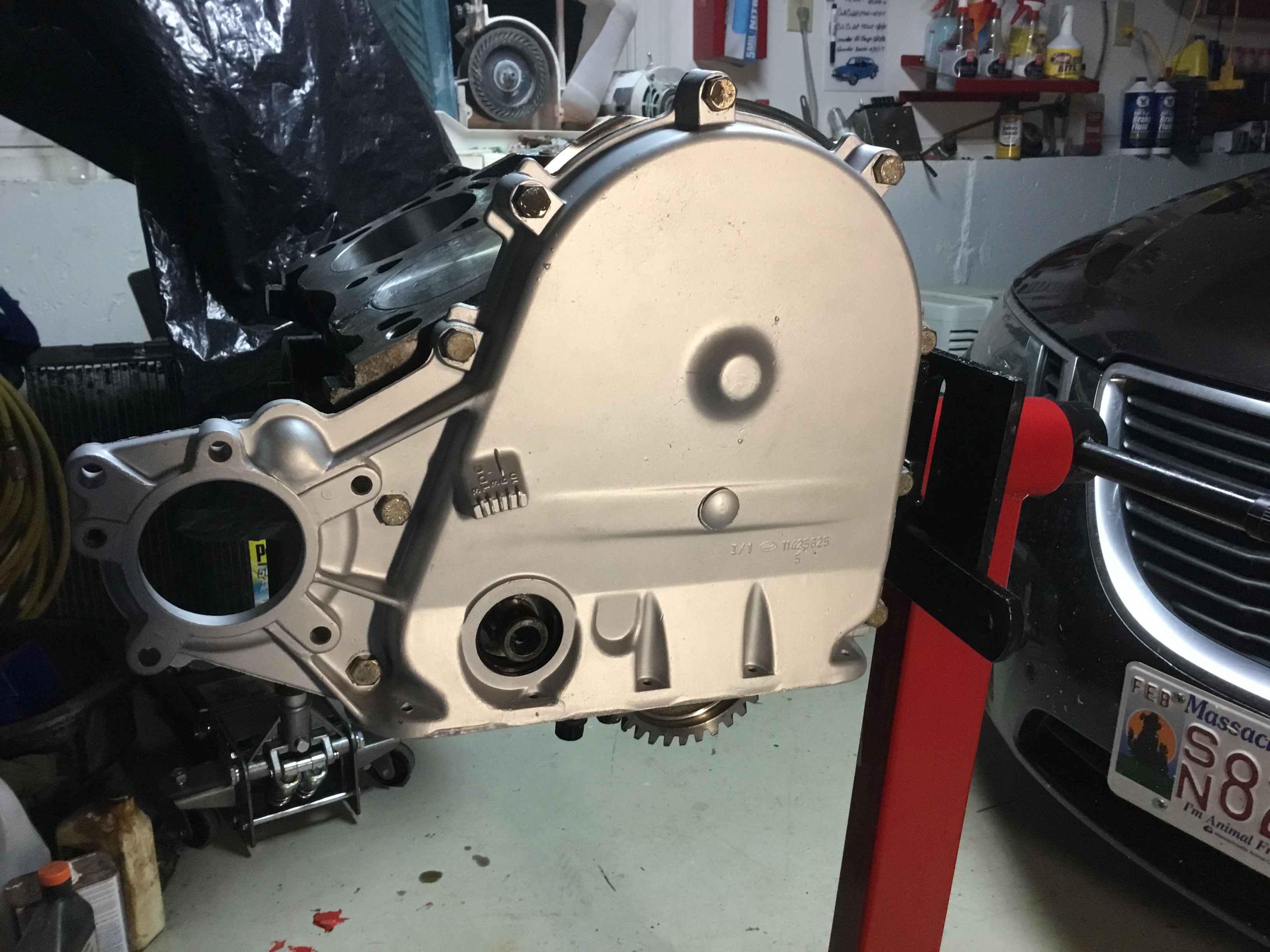

A trip to an auto parts store these days means you’ll be lucky if the sales associate can get the make, model, and year right. If you own a Toyota Camry or Ford F150, you’ll probably be fine… maybe… But good luck getting the best clutch for your V4 gearbox at your local chain auto parts store. Or a refurbished distributor. Or custom forged pistons. To make my point, my brother recently walked into a local auto parts store in his hometown. He lugged in the 40 pound battery out of his Corvette and plopped it onto the parts counter. The associate looked at him, and says: “Let me guess, you’re the guy that just called about the brake calipers…?”

But dealing with Jack was more than just dealing with an expert. Or a guy that gets you the right part. You felt like you were dealing with someone who cared enough about your project to listen. And although he definitely knew more than you, he never talked down to you. As a Sonett rookie, I was ready to build a 200+ HP V4. He could have laughed me off, but instead found ways to help me get where I wanted to go. And that’s always it, we have someplace we want to go, don’t we? Whether it’s building a perfectly restored vintage Saab, buying our dream home, or seeing the kids succeed, we have a destination in mind. I had heard rumblings that Jack had wanted to retire, but never reached that station. But his list of accomplishments was long: served in the US Air Force, SCCA racing legend, aircraft mechanic, and more.

Often times we get tunnel vision, and the destination becomes all we can think about. To the point where we miss the whole reason for living, and that is the journey itself. After all, the Saab motto was “Find your own road”, was it not? Jack lived the vintage Saab life, and you felt his passion even through the phone from hundreds of miles away. I think there is a lesson to be learned there. Even into his late eighties, his passion kept him young at heart and sharp as a tack to the end. We have to keep piling up the good times and great memories, because at the end of the day, that is all we really have. As an auto enthusiast, we all know that most of the time, the journey is better than the destination. Jack may not have been pulling 1.0 G in the corners these days, but he didn’t put his life on hold just because he wasn’t racing anymore. He backed up, but he didn’t give up.

I had second thoughts about writing this. After all, I’m a nobody. I’m not a vintage Saab expert like Jack. I wasn’t his best friend. Nor a longtime business associate. But I wanted to write something that memorialized him, his passion for Sonetts, and his legendary work ethic. He made the road trip for as long as he could, and brightened the lives of everyone he talked to. I cannot, for the life of me, think of a single time that anyone ever had a bad word to say about Jack Lawrence. He didn’t just make his life the best journey he could, he made every one else’s the best he could too. And that reminds me of something I once read…

The Station

Tucked away in our subconscious is an idyllic vision. We see ourselves on a long trip that spans the continent. We are traveling by train. Out the windows we drink in the passing scene of cars on nearby highways, of children waving at a crossing, of cattle grazing on a distant hillside, of smoke pouring from a power plant, of row upon row of corn and wheat, of flatlands and

valleys, of mountains and rolling hillsides, of city skylines and village halls.

But uppermost in our minds is the final destination.

On a certain day, at a certain hour we will pull into the station. Bands will be playing and flags waving. Once we get there so many wonderful dreams will come true, and the pieces of our lives will fit together like a completed

jigsaw puzzle. How restlessly we pace the aisles, damning the minutes for loitering – waiting, waiting, waiting for the station. “When we reach the station, that will be it!” we cry. “When I’m 18.” “When I buy a new 450SL

Mercedes Benz!” “When I put the last kid through college.” “When I have paid off the mortgage!” “When I get a promotion.” “When I reach the age of retirement, I shall live happily ever after!”

Sooner or later we must realize there is no station, no one place to arrive at once and for all. The true joy of life is the trip. The station is only a dream. It constantly outdistances us. “Relish the moment” is a good motto, especially when coupled with Psalm 118:24: “This is the day which the Lord hath made; we will rejoice and be glad in it.” It isn’t the burdens of today that drive men mad. It is the regrets over yesterday and the fear of tomorrow. Regret and fear are twin thieves who rob us of today.

So, stop pacing the aisles and counting the miles. Instead, climb more mountains, eat more ice cream, go barefoot more often, swim more rivers, watch more sunsets, laugh more, cry less. Life must be lived as we go along. The station will come soon enough.

- Robert J. Hastings

RIP to the late, great, John “Jack” Lawrence.

https://www.post-journal.com/obituaries/2020/09/john-h-jack-lawrence/

JMC 10/4/2020

So, here are the details:

So, here are the details: